the principle of brinell hardness testing|brinell hardness test formula : bulk The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test . Economize tempo agendando um horário online com Dr. Samuel Lucas do Nascimento Reis, Cirurgião de cabeça e pescoço, Cirurgião geral em Belo Horizonte. Leia os comentários dos pacientes, escolha uma data e faça o agendamento em alguns segundos Cirurgia De Tireoide, Cirurgia De Glandula Salivar, Cirurgia De Laringe.

{plog:ftitle_list}

4 de ago. de 2023 · 969 5 3. Vazados da 👹Deep WEEB👹. 4 Aug 2023, 01:58. @VazouDeeep. 541 1 1. 5 last posts shown. Show more.

The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped . In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.

The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to 3000Kgf, for a specified time period, usually .

Theory and Principle of Brinell Test. The test consists of forcing a steel ball of diameter ' D' under a load ' P' into the specimen for a known time and measuring the mean diameter ' d ' of the impression left on the surface after removal of .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .

Principles of Brinell Hardness Test. The Brinell hardness test works under two stages. The indenter is brought into contact with the test sample in the first step, and the indenter is then .

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell Hardness Number HB is .The Brinell method has the following advantages: The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic constituents of the material), thereby forming a .Brinell hardness testing is extensively used in the casting industry to assess the hardness and quality of cast materials, such as cast iron, aluminum alloys, and bronze. . 2.3 Functional and Calculation Principle for Brinell Sample Surface Force (F) HBW = Brinell Hardness HBW = Constant x HBW = 0.102 x d 1= (Mean Indentation-Ø) Test Load F 2F

Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. . Students learn about hardness .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested using another test method, e.g., castings and forgings. Brinell testing often use a very high test load (3000 . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Brinell hardness (1) Principle. To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration.

The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left. The method proved reliable and in 1900 the . 1.2 This test method includes requirements for the use of portable Brinell hardness testing machines that measure Brinell hardness by the Brinell hardness test principle and can meet the requirements of this test method, including the direct and indirect verifications of the testing machine. Portable Brinell hardness testing machines that cannot .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

Measuring range Portable Brinell hardness tester is the same with King Brinell hardness tester. Before coming out of the factory, it can be selected 500kg, 750kg, 1000kg, 1500kg, 3000kg test force .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test.

Brinell hardness test charts. The approximate Brinell number for loads are: Load (kg) Brinell hardness number: 500: 26 – 100: 1500: 80 – 300: 3000: 160 – 600: While the Brinell hardness test is most commonly used to test metals and alloys, it can be used on other materials too.The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures. . Theory and Principle of Brinell Test.The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings. . Students learn about hardness testing principles, equipment operation, and data analysis, preparing them for careers in industry and research.

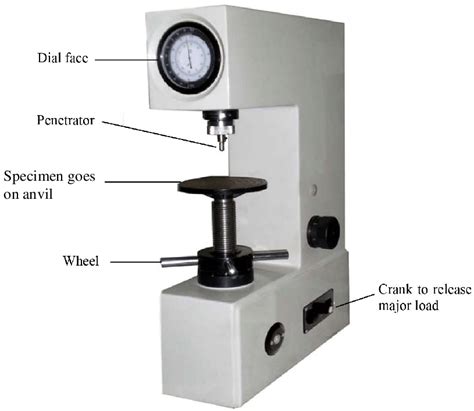

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .6.1 Principle of Testing. The Brinell hardness test consists of forming an indentation by forcing a standard spherical ball indenter into the surface of the material under a definite static load applied for a standard period of time. The standard Brinell hardness tester operates usually under hydraulic pressure that applies force.Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; . Knoop Hardness Testing: Employs a diamond penetrator to impress a sample; Shore Hardness Testing: Uses the principle of measuring the resistance of a material to indentation; Advanced Techniques in Hardness .

The 2 steps for the principle of the Brinell test method. The general principle of the Brinell indentation hardness test consists of two steps: Step 1 – The indenter is brought into contact with the test specimen in a direction perpendicular to the surface, and the test force is applied (Apply the test force within 1 to 8 s). The test force is held for a specified dwell time and then .The brand-new Krautkramer MIC 20 combines the two most successfully applied portable hardness testing principles in one instrument. Whether you want to use the UCI principle or the dynamic Rebound testing method – the MIC 20 offers both possibilities. . As in standard Vickers or Brinell hardness testing, the question as to the size of the . This article discusses methods and the principles behind hardness testing. Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. . Among the standardized optical hardness testing methods are the Brinell hardness test (ISO 6506, ASTM E10), the Knoop hardness .

Principles of Brinell Hardness Test. The Brinell hardness test works under two stages. The indenter is brought into contact with the test sample in the first step, and the indenter is then subjected to a certain amount of force. After a predetermined dwell period, the force is applied and then released. The indent diameter is measured in at . Hardness testers are complex in design but simple in principle, operation and application. They measure the hardness of a material as its ability to resist permanent deformation from an applied force. . Brinell hardness test is an indentation hardness test. It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a .

5.1 Brinell Hardness Test Principle—The general principle of the Brinell indentation hardness test consists of two steps (see Fig. 1). 5.1.1 Step 1—The indenter is brought into contact with the test specimen in a direction perpendicular to the surface, and the test force F is applied. The test force is held for a specifiedThe Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is measured. The total test force is applied in two stages to eliminate errors caused due to the roughness of the surface and measurement. . Brinell Hardness Test for Metals. Vickers Hardness .The hardness of metals can be tested by 12 different hardness tests and the Brinell Hardness test is the oldest technique to measure the hardness of metals but is widely used. In this blog, we will discuss only Brinell Hardness test methods, including principle and theory, applications, advantages and disadvantages.Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .

What Is Hardness Testing? Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for comparing and selecting materials, as well as ensuring quality control in manufacturing or hardening processes.

rockwell hardness tester procedure pdf

hardness tester lab report pdf

hardness test lab report pdf

web31 de out. de 2023 · Por GIGA-SENA. O sorteio do concurso 6280 ocorreu no dia 31 de outubro de 2023 e o prêmio principal foi estimado em R$ R$ 3.000.000,00 (três milhões de reais) para quem acertar o resultado da Quina 6280. Quem acertar a QUADRA com 4 (quatro) números, o TERNO com 3 (três) números ou o DUQUE com 2 (dois) números .

the principle of brinell hardness testing|brinell hardness test formula